Description

BRANDS WE DEALS WITH

Alfa-Laval, Westfalia, Mitsubishi, Tomoe

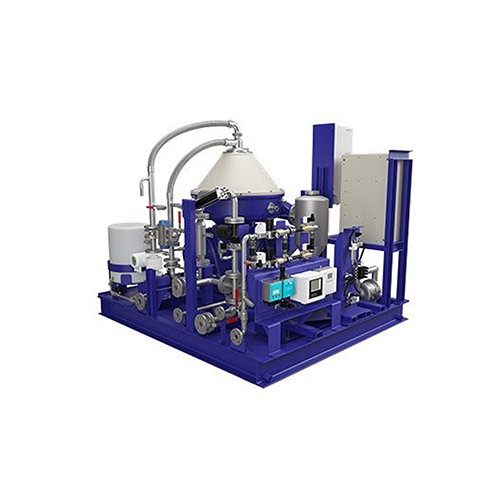

Complete Purifiers and Separators

Purifiers and separators are used to remove contaminants and water from fuel and lubricating oils, ensuring the purity and optimal performance of these fluids.

Types of Purifiers and Separators:

- Centrifugal Separators: Use centrifugal force to separate different components based on their densities.

- Gravity Separators: Rely on gravity to separate solids and liquids of different densities.

- Magnetic Separators: Remove ferromagnetic materials from the liquid.

- Filter Separators: Use filtering media to separate solid particles from liquids.

Components of Purifiers and Separators:

- Bowl Assembly: The core component where separation occurs. It spins at high speed to create centrifugal force.

- Drive Mechanism: Includes motors, belts, and gears that drive the bowl.

- Control Systems: Automated systems that regulate the operation of the purifier or separator.

- Inlet and Outlet Ports: Entry and exit points for the fluid being processed.

- Discharge Mechanism: System for removing separated impurities.

Common Spare Parts for Purifiers and Separators:

- Separation Discs: Essential for the separation process within the bowl assembly.

- Gaskets and Seals: Prevent leaks and ensure the integrity of the separation process.

- Bearings: Enable smooth and efficient rotation of the bowl assembly.

- O-Rings: Used in various parts to maintain airtight and leak-proof seals.

- Nozzles: Control the flow and pressure of the fluid entering the separator.

- Wear Rings: Protect the separator’s components from wear due to friction.

- Drive Belts: Transfer power from the motor to the separator’s bowl.

- Sensors and Control Units: Monitor and adjust the operation parameters to maintain optimal performance.

- Filters: Remove larger impurities before the fluid enters the separator to prevent clogging and wear.

- Ejectors: Used in self-cleaning purifiers to expel separated impurities.