Description

BRANDS WE DEALS WITH

MAN-B&W, Sulzer, Pielstick, Stork, Deutz-MWM, MAK, Ruston, SKL, B&W Alpha, Wartsila, Mitsubishi, Akasaka, Hanshin, Matika, Niigata, Caterpillar, Cummins Detroit Diesel, Bergen, Nohab, Dorman, Paxman, Mirrless , WH Allen, YANMAR, Daihatsu

Main Engines

Main engines are the primary source of propulsion for ships and large industrial machinery. They are designed to provide continuous power and are typically robust and large-scale.

Types of Main Engines:

- Diesel Engines: Common in marine applications due to their efficiency and reliability.

- Gas Turbine Engines: Used for their high power-to-weight ratio.

- Steam Turbines: Mostly used in older ships and certain industrial applications.

Common Spare Parts for Main Engines:

- Pistons and Piston Rings: Vital for the engine’s compression and combustion processes.

- Cylinder Liners: Ensure a smooth surface for piston movement.

- Connecting Rods: Transfer the motion from the piston to the crankshaft.

- Crankshafts: Convert the linear motion of pistons into rotational motion.

- Bearings: Reduce friction between moving parts.

- Valves and Valve Seats: Regulate the flow of air and fuel into the engine and the exhaust gases out of the engine.

- Fuel Injectors: Critical for proper fuel delivery and atomization.

- Turbochargers: Increase the engine’s efficiency and power output.

- Gaskets and Seals: Prevent leaks and ensure proper compression.

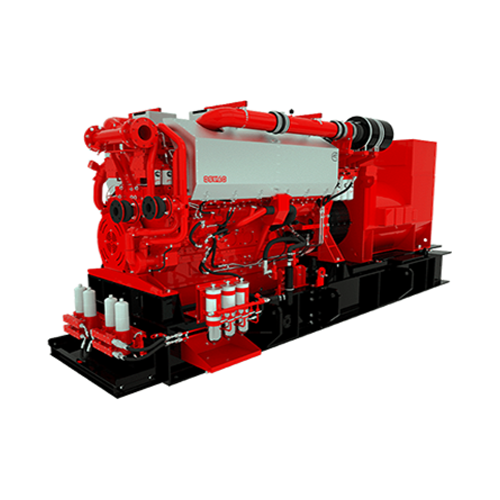

Auxiliary Engines

Auxiliary engines provide power for non-propulsion purposes on ships and in industrial settings. They typically run generators, pumps, compressors, and other essential equipment.

Types of Auxiliary Engines:

- Diesel Generators: Common for power generation on ships and in remote locations.

- Gas Generators: Used where gas supply is reliable and preferred.

- Steam Generators: Provide additional power and are often used in conjunction with steam turbines.

Common Spare Parts for Auxiliary Engines:

- Filters (Oil, Air, Fuel): Ensure clean supply of oil, air, and fuel to the engine.

- Belts and Pulleys: Drive various auxiliary components.

- Impellers and Bearings for Pumps: Essential for the operation of pumps driven by auxiliary engines.

- Electrical Components (Alternators, Regulators, Relays): Critical for power generation and distribution.

- Coolers and Heat Exchangers: Maintain proper operating temperatures.

- Exhaust Components (Mufflers, Catalytic Converters): Manage emissions and reduce noise.

- Sensors and Monitoring Equipment: Ensure safe and efficient operation through constant monitoring.

Importance of Spare Parts Inventory

Maintaining a comprehensive inventory of spare parts for both main and auxiliary engines is crucial for several reasons:

- Minimizing Downtime: Quick replacement of faulty parts ensures continuous operation.

- Cost Efficiency: Prevents expensive emergency repairs and extended downtime.

- Safety: Ensures the safety of operations by replacing worn-out parts before they fail.

- Compliance: Helps in adhering to maintenance schedules and regulatory requirements.